press release

Brewing world

18.08.2025

NEW BUSINESS SEGMENT BREWER'S YEAST

ZETTL roller dryer

at Tremonis GmbH in Dortmund

In 2023, the average beer consumption in Germany was 88 liters of beer per capita per year, according to statista.com. This makes Germany one of the most beer-drinking countries in Europe. However, appearances are deceptive: beer consumption has been declining for years. In times when giving up alcohol is becoming increasingly important for many consumers, breweries also have to look around and tap into new business areas. The following article highlights a cooperation between Tremonis GmbH in Dortmund and Zettl GmbH, Munich, in which brewer's yeast is refined into animal feed

An example that can be transferred to smaller breweries in many ways.

Brewing produces large quantities of valuable and nutritious by-products such as brewer's yeast and brewer's spent grains, which are often used as supplementary feed in animal husbandry. Brewer's yeast is particularly rich in natural B vitamins. The biological value of the feed proteins in brewer's yeast is excellent. Pure brewer's yeast contains over 43 percent protein. The content of valuable amino acids such as lysine is also very high at around three percent. Brewer's yeast accelerates the metabolism and resistance of the animals due to its high vitamin content.

Tremonis GmbH is part of the Radeberger Group and processes brewer's grains and brewer's yeast into high-quality animal feed at its site in Dortmund. Breweries from all over Germany supply the raw product. From 35,000 m³/a of liquid brewer's yeast, 2,000 t/a of dried brewer's yeast, 1 million liters of industrial alcohol and 500 t of mineral feed mixtures are produced. The company attaches great importance to energy-efficient plants. The focus is not only on generating heat, but also on recovering heat from the various production steps. This goes so far that the biogas produced in the waste water plant is burned in a CHP unit to generate its own electricity and heat.

Refining brewer's yeast into animal feed also pays off for smaller breweries

Brewer's yeast refinement is also worthwhile for smaller breweries with smaller batches that want to sell their yeast as a feed supplement or as an additive. The drying process using a roller dryer offers several technical and economic advantages over spray drying or paddle drying:

- Efficient and direct drying of brewer's yeast without prior spray atomization (no additional effort)

- Short drying times in just a few seconds, preservation of valuable vitamins and amino acids (better product quality)

- Small footprint, simple technology (ideal for smaller breweries with limited space and budget)

- Good economy with smaller filling.

Spray drying or paddle drying are only worthwhile for larger quantities. The roller dryer is economical from just a few hundred liters of brewer's yeast. The economic efficiency is increased by using the waste heat, high-quality animal feed marketing and cooperative use with other breweries.

Roller dryer from a few hundred liters of brewer's yeast

Roller dryers are available in different throughput capacities. Capacities of 130 to 770 kg/h can be processed in four different device types, thus opening up new marketing potential for smaller breweries with just a few hundred liters of brewer's yeast.

| Throughput/h Yeast with 74 % H²O |

Steam consumption/h in kg at 3.5 bar |

Quantity of dry product/h with 7 % H²O residual moisture |

| 770 kg | 548 kg | 215 kg |

| 340 kg | 242 kg | 95 kg |

| 216 kg | 153 kg | 60 kg |

| 130 kg | 92 kg | 36 kg |

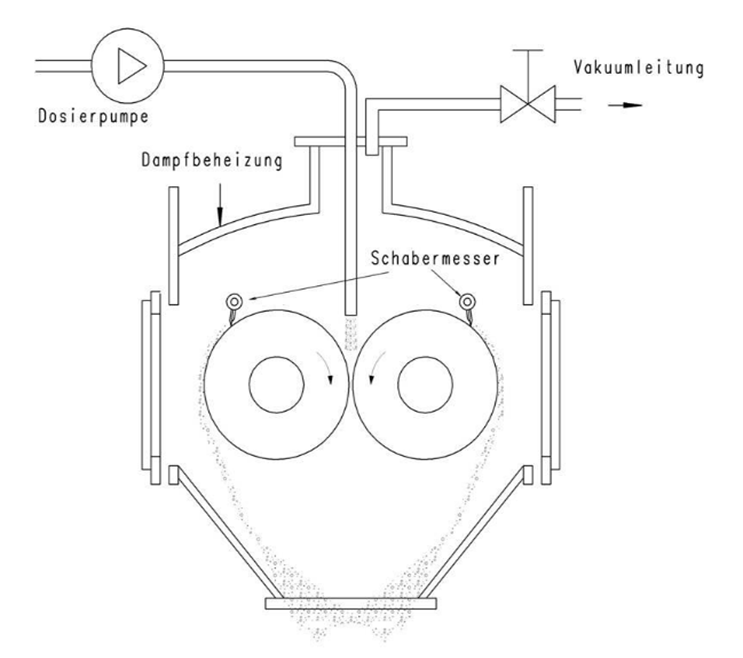

Functionality of the two-roller dryer

Roller dryers are used for the continuous drying of solutions, suspensions and pastes of different consistencies and viscosities. They are used wherever short drying times are required to maintain certain product properties, such as with yeast. In two-roller dryers, the wet product to be dried is applied to rotating, heated hollow rollers in a thin, uniform layer thickness using special devices. The moisture evaporates during a partial rotation of the rollers.

The dried product is removed by scraper blades. Depending on the nature of the processed product, it accumulates as a film, in flakes or as a powder and can be fed to the next processing stage via appropriate conveyor systems. Compared to many other dryers, this design results in extremely short dwell times, which means that ingredients such as vitamins and minerals are retained. Drying under vacuum further enhances this effect, as the drying temperature can be significantly reduced. The constant temperature in the rollers, regardless of the heating medium, ensures consistent product quality.

The central product feed is located in the gusset area, i.e. the area where the two adjacent rollers almost touch each other with a roller gap of 0.3 mm. This enables precise and even distribution of the starting product above the roller gap over the entire length of the rollers. By rotating in opposite directions, a homogeneous product layer is formed on the hot roller surface, as both act as applicator rollers for the other. This leads to a uniform film of material on the roller surfaces and therefore to optimum drying.

The dried brewer's yeast is removed from the surface of the rollers using pneumatically operated scraper blades. The dry mass falls downwards past the drying rollers directly into screw conveyors. The smooth surface of the hard chrome-plated steel rollers leads to significantly reduced wear on the scraper blades. As a result, downtimes for blade changes as well as maintenance costs for regrinding and replacing blades can now be minimized. The dried brewer's yeast is then available for further processing.

The project

The collaboration began in 2020. Tremonis first simulated the technical processes in ZETTL's own technical center and then determined the requirements profile for the paddle dryer, which was finally ordered in 2022, delivered in 2023 and put into operation.

The dryer was designed according to Tremonis' specifications for throughput and energy consumption and further improved technologically in close cooperation between the specialists from commissioning to handover.

The dryer has a gross heating surface of 25 m². It can be operated continuously 24/7 under atmospheric conditions. It is currently used in three-shift operation from Monday to Friday. The brewer's yeast has a dry substance content of 25 percent in the inlet of the apparatus with a material feed of approx. 750 kg per hour. Between 180 - 200 kg of dried brewer's yeast with a dry matter content of 93 percent remains in the discharge, which is then conveyed via screw conveyors and various conveying lines to the subsequent packaging. The process engineering and economic evaluation was very good.

Technical specifications as an overview

| Gross heating surface | 25 m² |

| Mode of operation | Atmospheric pressure |

| Operation | 24 / 7 |

| DM content of brewer's yeast | in the inlet > 25 % |

| Inflow | 750 kg/h |

| DM content of dried brewer's yeast | 93 % |

| Discharge of dried brewer's yeast | 200 kg/h |

Economic aspects

The roller dryer holds its own against other drying processes such as spray dryers or paddle dryers and is ahead in terms of investment costs, space requirements, production yield, energy consumption, batch size and product protection. For example, the product no longer segregates before being applied to the roller surface, resulting in a homogeneous product film on the rollers. The rollers are no longer immersed in the product sump, but are fed from above. This results in a precisely defined application to the surface. There is also a longer contact time of the material to be dried on the roller surface, which results in a drier end product and higher energy efficiency of the heating steam used. There is no need to return excess product, as is the case with other drying processes.

The use of two rollers instead of just one reinforces the advantages. These effects will increase through more efficient use of steam and controlled steam regulation as well as better heat transfer with the materials used and modern steam conduction inside the new rollers.

Summary

By-products such as brewer's yeast are produced in large quantities during beer production. Brewer's yeast has been one of the most popular feed supplements in animal husbandry for many years. In a joint project between Tremonis GmbH and Zettl GmbH, the processing of brewer's yeast as a feed supplement is demonstrated.

A two-roller dryer was used, which promises precise and even distribution of the starting product. As a result, a homogeneous product layer forms on the hot roller surface, which leads to optimum drying. The dried brewer's yeast is removed using pneumatically operated scraper blades. Gentle drying ensures that the valuable ingredients are better preserved so that the yeast can be used as healthy protein feed in agriculture. The production of the feed with its own equipment is also interesting for TREMONIS as an additional source of income for smaller breweries.

The project is also transferable to smaller breweries and points to low entry barriers for yeast refinement. The roller dryer also offers significant advantages for smaller breweries. The most important points are an increase in drying capacity, short drying times, low space requirements and simple technology. The economic efficiency is also considerable for smaller batches. Roller drying is economical from just a few hundred liters of brewer's yeast.

Authors: Thomas Ahrens, Senior Sales Manager ZETTL GmbH, Karsten Gödicke, Head of Technical Center ZETTL GmbH, André Henning, Operations Manager TREMONIS GmbH

Optimization of technical processes

André Henning, Operations Manager TREMONIS GmbH (left), Karsten Gödicke, Head of Technical Center ZETTL GmbH