Product

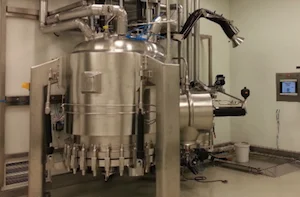

Agitator nutes and filter dryers

Agitator grooves are used for the mechanical solid-liquid separation of suspensions with low to high solids content. The solids are retained by a horizontally arranged permeable sieve bottom and the solids form a filter cake.

The separation process is accelerated by an overpressure in the upper process chamber or by a vacuum below the filter layer, or ideally by both.

A height-adjustable beam agitator can smooth or roughen the surface of the filter cake depending on the process requirements. This also makes it possible to re-suspend the filter cake.

The filter cake can be impinged with different washing liquids by means of one or more nozzle rings in the upper part and thus certain fractions can be liquefied and washed out of the filter cake.

By means of the agitator, the finished treated filter cake is then discharged via a side discharge valve and fed for further processing.

In the extended version of the agitator chute as a filter dryer, the process vessel, beam agitator and filter bottom can be heated or cooled. This means that after mechanical solid-liquid separation, thermal solid-liquid separation is also possible with the result that a significantly lower residual moisture content of the solids is achieved.

The cooling of the filter drier is particularly useful for crystallisation. The crystals formed in the suspension when exposed to cold can then be collected in the filter cake.

Due to the closed process chamber, grooving machines are also suitable for processing explosive, hazardous and toxic products. Depending on the requirements, the machines can be designed in ATEX version, in FDA food version or in pharmaceutical version according to cGMP.

The process control of the filter chutes can be automated. A PLC control with visualisation, with optional connection to a process control system, enables reproducible filtration with high quality requirements.

Process engineering

Separation of solids and liquids

filit

homogenise

distill

inert

crystallise

mix

re-suspend

stir

dry

evaporate

one, wash several times

Sizes and materials

Grooves can be supplied from laboratory size with approx. 0.15 m² filter surface to large apparatus with filter surfaces of over 16 m².

Depending on the products to be processed, simple stainless steels, highly corrosion-resistant stainless steels and nickel-based alloys can be used as materials for the parts of the grooves that come into contact with the product.