Product

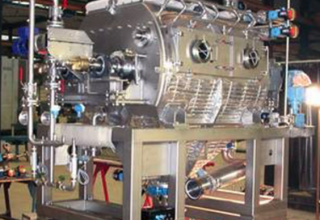

Vacuum roller dryer

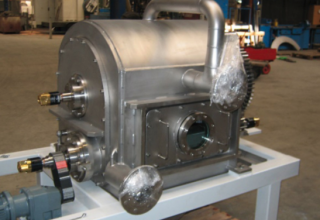

Roller dryers are used for the thermal solid-liquid separation of solutions and suspensions of various consistencies and viscosities with low to high solid contents.

In particular, sticky products and products with a tendency to adhere, which cannot be processed with other drying methods, can be dried very well with this technique.

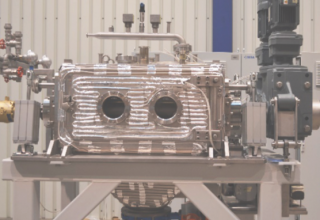

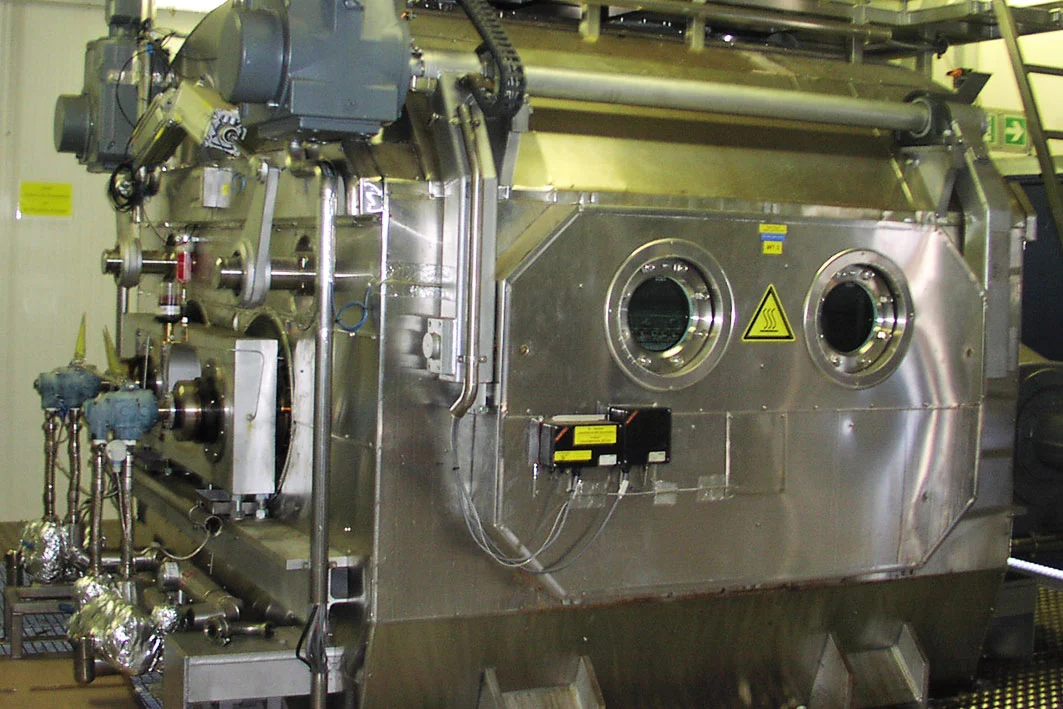

Free-flowing products or materials containing solids larger than approx. 50 µm are not suitable for roller dryers. In the roller dryer, the input product is continuously distributed in a uniformly thin layer onto the heated rollers by means of a special distribution device. During the continuous rotation of the rollers, the liquid part of the product evaporates. The solid, dried portion is separated from the roller by the adjacent doctor blades and, depending on the design, is taken up in a collecting container or continuously discharged.

The product chamber is under vacuum and thus enables a particularly gentle and energy-saving drying process due to lower boiling points in the vacuum and short dwell times on the hot rollers.

Due to the closed process chamber, roller dryers are also suitable for processing explosive, hazardous and toxic products. Depending on the requirements, the machines can be designed in ATEX version, in FDA food version or in pharmaceutical version according to cGMP.

The process control of the roller dryers can be automated. A PLC control with visualization, with optional connection to a process control system, enables reproducible filtration with high quality requirements.

Process engineering

Separate solids from

Separating liquids

dry

distill

evaporate

crystallise

melt

Solvent recovery

freeze

Sizes and materials

Roller dryers can be supplied from laboratory size with a heating surface of approx. 0.15 m² up to large units with heating surfaces of over 25 m².

The material used for the rollers in contact with the product can be carbon steel, stainless steel, hard chrome or hard metal. Stainless steel up to nickel-based alloys can be used as the material for all other parts in contact with the product.