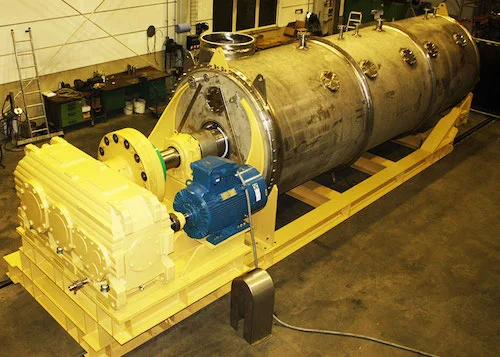

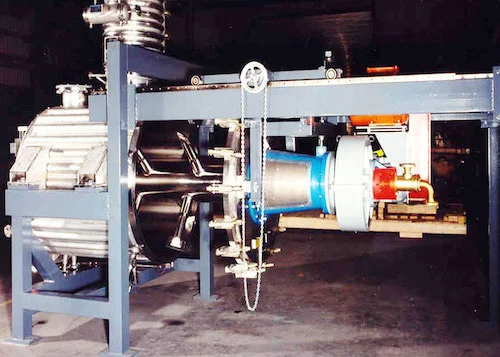

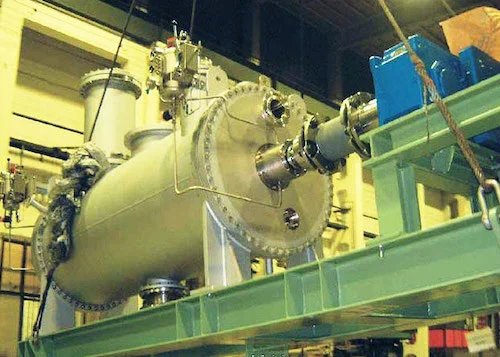

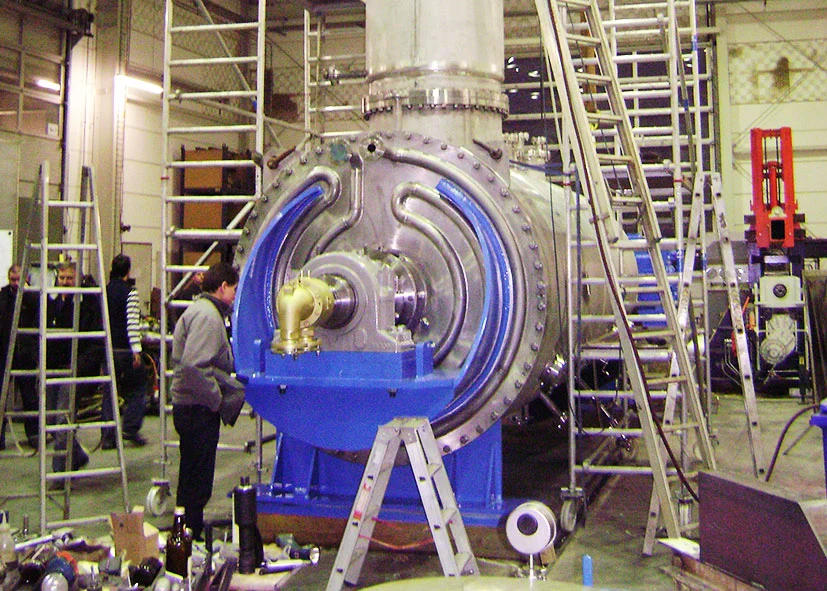

Paddle dryer/reactor

Product

ZETTL ETS® Dryer

Liquid-laden solids from pasty to free-flowing consistency

are dried with ZETTL paddle dryers in an energy-conscious, gentle and

environmentally friendly manner. We supply slow and fast running

dryers for batch or continuous operation.

Vacuum paddle dryers enable gentle drying. With

optimised space requirement, a maximum of heat transfer surface is brought to

application. Another component is also the former

BUSS paddle dryer programme.

We dry your products in an energy-conscious, gentle and environmentally friendly way.

Depending on the respective processes and requirements, we supply slow and fast running dryers.

Variants

The following are used for specific tasks

ETS® DRYER Type BT

As a fast-running mixer dryer (up to 200 rpm), also for mechanically insensitive products

Sizes: 100 to 20,000 l capacity.

ETS® DRYER Type CT

As a continuously operating mixer dryer

Sizes: 3,000 l/h to 50,000 l/h.

paddle dryerstype S and SF

As slow-running batch and continuous paddle dryers (up to 20 rpm). These are suitable for difficult operating conditions such as drying very viscous, pasty or sensitive drying materials.

BUSS paddle dryers

The former BUSS paddle dryer programme with service and spare parts service for all BUSS paddle dryers supplied since 1970 is integrated in our delivery and service programme.

Dryers up to a size of 3000 l can be designed as machines with bearings on one side; if required, with extendable and temperature-controlled shaft. This design offers advantages for frequent product changes, among other things.

Process engineering

dry

react

distill

evaporate

calcine

sterilise

degas

homogenise

mix

Materials

Process engineering tasks require materials that meet the requirements. Our machines can be made from all weldable materials such as steel, stainless steel, duplex steel, Hastelloy, titanium and special materials. Furthermore, clad sheets are used.