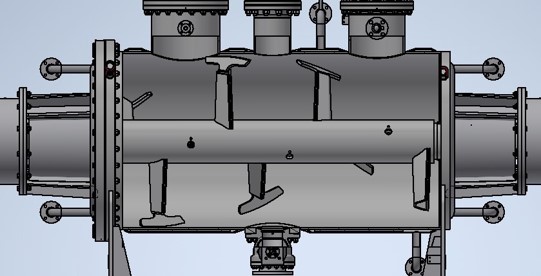

RPD - Thermal cleaning device

Technology

RPD - Thermal cleaning device

Remediation technology for large quantities

The RPD is a highly efficient thermal cleaning system that is particularly suitable for processing large quantities of contaminated soil, excavated material, drilling mud, sludge, etc. The RPD uses thermal cleaning technology to separate pollutants from contaminated material in a safe and energy-efficient manner and is designed for 24/7 operation. It operates under vacuum and therefore requires less energy than comparable techniques during the process to gasify hydrocarbons and pollutants.

The RPD is available in sizes from 1,000 l to 30,000 l with parallel dryers. The RPD solution is a semi-mobile unit that is preferably assembled on site. At the end of a job, it can be dismantled and transported in parts to be reassembled at a suitable location for the next project.

Purchase specification

Complete semi-mobile system with the following units:

- Feeding system (without shredding)

- Two vacuum dryers with 20 m³ each

- Vacuum and condensation systems for water condensate and oil/water/pollutant condensate

- Process cooling

- Thermal oil heating 400°C

- Electric heating up to 550°C

- Product cooling and remoistening

- Emptying system in local emptying box/area

- Exhaust gas treatment system according to local standards

- Complete steel construction, frame, stairs and platforms for the system

- Complete electrical wiring of the system

- Container for switch cabinets and operator room

Options:

- Parallel dryers

- ATEX

- Cooling unit

- Exhaust air purification

- UPS

- Emergency power supply

- Cooling mixer

- Condensation water treatment system

- Support with permits

Technical data

|

Model: (up to 550°C thermal oil heating) |

RPD 10000 10.000 l |

RPD 5000 5.000 l |

RPD 1000 1.000 l |

| Footprint: | 14 m x 5 m x 12 m | 10 m x 4 m x 9 m | 7 m x 3 m x 6 m |

| Heating (electric or gas): | 400 kW | 200 kW | 80 kW |

| Power consumption: | 280 kW | 140 kW | 70 kW |