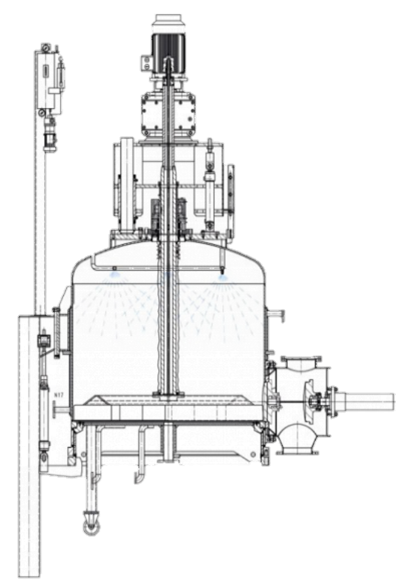

Filter dryer

Technology

Filter dryer

Filter dryers are ideally suited for filtration of suspensions with low or even high solids content and further treatment of the resulting filter cake.

Process steps such as slurrying, washing and drying can therefore be carried out in the same machine.

The liquid is separated mechanically using vacuum or overpressure or a combination of both. After the mechanical separation of the liquid portion, the residual moisture is thermally evaporated to achieve a high degree of drying of the dry substance. For this purpose, the nutsche containers and often also the agitator are designed to be heated. A special agitator improves the efficiency of filtration and drying and enables the solids to be discharged mechanically.

ZETTL (vacuum/pressure) nutsches consist of a self-contained, vacuum-tight and heated housing. Filter media with different mesh widths/pore sizes can be attached to the filter base.

Application

pharmaceutical industry:

Active ingredients

Penicillin

Antibiotics

Syntetic vitamins

Proteins

Plant extracts

Chemical industry:

Polymers

Pigments

Pesticides

Surfactants

Fungicides

Cosmetic ingredients

TECHNICAL DATA

| Working temperature: | -10° to 200° C |

| Working pressure: | - 1 to 10 bar |

| Filter surface: | 0.12 to 12 m² |

| Suspension volume: | 50 to 12,000 liters |

| Material: | all stainless steels up to Hastelloy C22 |

| Execution option: | ATEX | FDA | GMP | CIP |